Electronics

The main mission of the electronics department is the study, design and implementation of data control, acquisition and processing systems. These activities are principally dedicated to experiments in particle physics, astroparticle physics and observational cosmology, but can also be directed towards external partnerships and used within new interdisciplinary frameworks.

The department operates by managing or participating in technological projects related to its skills. We interact with physicists from all the disciplines represented in the laboratory and take charge of developments from the feasibility study phase of projects, through to their completion and implementation.

The electronics department can also make its expertise available to external partners or companies, and can study their specific projects.

Our vocation also includes the transmission of our expertise and knowledge: we work with various universities and engineering schools in the region and regularly welcome students (DUT, BTS, Master I and II and PhD).

Our work is regularly presented at international conferences and published in scientific journals. Some of our developments are protected by patents

Head of the department: Patrick Pangaud

Micro-electronics group:

- Patrick Breugnon

- Denis Fougeron

- Mohsine Menouni

- Patrick Pangaud

- Danwei Xu (CDD)

- Karima Garradhi (CDD)

- Roua Boudagga (PhD Student)

- Emilio Mariton (apprentice)

- Ilian Medebbeur (apprentice)

Data acquisition architectures and systems:

- Bernard Dinkespiler(Saphir)

- Fabrice Gensolen

- Frédéric Hachon

- Julien Langouët

- Jérôme Royon

- Franck Salomon

- Stéphane Théraube

- Clément Chollet (CDD)

- Léo Martin (CDD)

- Costy Nassif-Mattar (apprenti)

Design and integration:

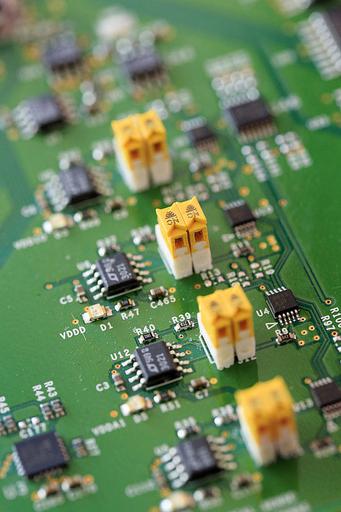

The accomplishments of the electronics department for physics experiments at particle accelerators, in the deep sea and in space have allowed us to develop a quality-based approach that is essential to meet modern reliability requirements.

Our skills include:

-

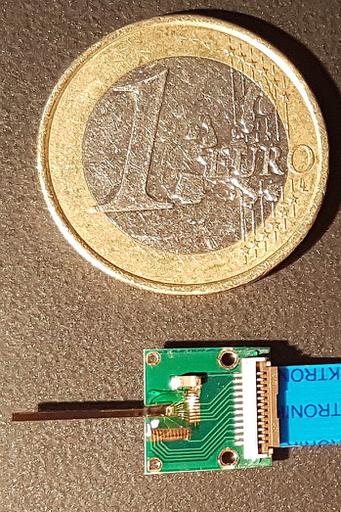

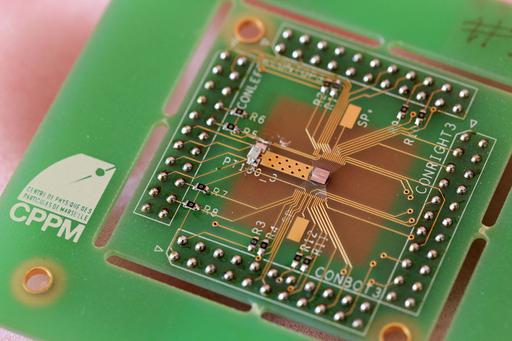

the design and testing of analog low noise, low power consumption, radiation tolerant ASICs (Application Specific Integrated Circuits) for physics detectors. In particular CPPM has contributed greatly to the invention and development of hybrid pixel detectors, which are now widely used in both particle physics and X-ray imaging;

-

the development of very high-speed digital acquisition cards. Work recognized at the international level and which has positioned us as a leader in this field of development, using the latest generation FPGAs (Field Programmable Gate Arrays);

-

the development of electrical energy distribution solutions: particularly the development and implementation of underwater detector power distribution networks with constraints of great depth (> 2500m) long distance from shore (> 40 km) and multi-kW distributed power;

-

the implementation of automated test benches and control systems, together with the interface controls and embedded firmware essential to validate the systems developed.

We also have highly specialized know-how in wiring, micro-wiring and the production of high performance electronic boards (IPC standard).

Computer Aided Design (CAD) tools play a very important role at all levels in the design, development, integration and maintenance of our projects. The corresponding expertise is an integral part of the department's know-how.

Achievements with particle accelerators

These developments are based on the various particle detectors installed at CERN's LHC

-

Development for ATLAS detector

-

Development for LHCb detector

We are in charge of the acquisition electronics for the future version of the LHCb experiment. This electronics will read in real time all the data of the experiment, i.e. 32 Terabits/s. It will also distribute control information and time information to all sub-detectors and review their states.

At the heart of this system, there is a complex electronic board developed at CPPM. It hosts the powerful ARRIA10 FPGA (programmable circuit) from INTEL/ALTERA which interfaces to 50 bi-directional optical links at 10 Gbits/s each, representing a consolidated bandwidth of nearly 500 Gbits/s in each direction. The board has a PCI Express format (to be inserted in a server) and allows a very close coupling between the FPGA and the central unit of the server with a bandwidth of 112 Gbits/s.

Nearly 700 cards are being manufactured for the LHCb detector update, scheduled for 2019.

This electronics is flexible enough to meet the needs in other areas such as the ALICE experiment or the µ3e experiment.

We can envisage others applications such as astroparticle experiments or dedicated to medical imaging.

Achievements with astroparticle experiments

- Conception et réalisation du système d’alimentation et de distribution de puissance

Achievements in observational cosmology experiments

-

R&D on a part of the filter exchange system for LSST telescope

-

Qualification of InfraRed (IR) detectors foe the Euclid satelite

Interdisciplinary Achievements

- Development for bio-medical imaging

We have been involved in the MAPSSIC project since 2016, a collaboration between the IMNC laboratory which is the initiator, IPHC, CRNL and NeuroPSI. This involves designing an intracerebral imaging device of the PET type for rodents free of their movements, in order to help study and develop drugs for addiction diseases, or memory disorders (Parkinson, Alzheimer for example).

-

Development for nuclear decommissioning

-

Development for plasma diagnostics in the future ITER reactor

-

Development for hadron-therapy

-

Development for general purposes instruments

Detector and Data

The laboratory's Detectors and Data department is structured around two activities:

The IT development with two axes:

-

Applied computing for the implementation of systems specific to physics experiments. This concerns the installation of software packages used in simulation, reconstruction and data analysis;

-

Instrumental Informatics for the study and realization programs of control and acquisition systems:

- Control and command of distributed systems processing large data flows in real time;

- Fugitive data acquisition, filtering, formatting and assembly;

- Inter-machine and inter-process communications.

The instrumentation engineer is involved in different phases of the project in a particle physics detector which is a complex measuring instrument combining a large number of technologies.

- definition of detection subsets and interfaces

- realization of test benches

- performing integration tests

- measurement analysis and calibration

Head of department: Aurélia Secroun

Instrumentation team

- Pierre Barrillon

- Marie-Ange Cordier

- Naomie De Araujo

- Farès Djama

- Mathieu Dupont

- Alexander Enzenhöfer

- Sylvain Henry

- Pascale Keller

- Nick Lumb

- Marie Tourneur-Silvain

Physics support team:

- Thomas Auphan

- Jurgen Brunner

- Franca Cassol

- Nicolas Fourmanoit

- Smaïn Kermiche

- Edith Knoops

- Emmanuel Le Guirriec

- Andrei Tsaregorodtsev

- Julien Zoubian

Instrumental computing development team:

- William Assal

- Amira Bouzourene (Apprentice)

- Malaury Bertin (Apprentice)

- Dirk Hoffmann

- Julien Houlès

- Danièle Laugier

- Théo Pariset (Apprenti)

The engineers of the Detectors and Data department have developed skills in the following fields:

-

Project:

- Project or sub-project management

- Drawing up specifications and test reports

-

Real Time developments

- Rapid extraction of large amounts of fugitive data.

- Fast and secure data transfer from remote networks

- Slow control of infrastructures and sensors

-

Developments for Physics

- Detector and sensor simulation

- Software development in different programming languages

-

Hardware:

- Development and detectors design

- Set up and characterization of photodetectors (PMT, SiPM, ...)

- Realization of specific test bench

- Calibration and integration of subsystems

- Subassemblies qualification

- Software:

- Simulation, reconstruction, monitoring

- Signal processing, data analysis

- Specific developments in high energy physics

- Microelectronics:

- Microcircuit testing and integration

- Analysis of radiation effects on microcircuits

- Characterization of specific detectors

- Cooling and gas analysis:

- Flow measurement by sonar system

- Gas mixture analysis

- Noble Gas recapture

- Bio-medical imaging systems:

- Specific detectors

- Image processing

- Hostile environment:

- Marine: deployment and connection of detection lines, underwater acoustics

- Space: clean room, cryostat

The engineers of the Detectors and Data department have responsibilities in the following experiments:

-

ATLAS

- Responsible for all pixel and insertable-B layer (IBL) software:

- Simulation, reconstruction, monitoring, databases (calibration, conditions...), performances...

- Contribution to the simulation of CMOS meters for the next ATLAS trajectograph, the ITK (installation planned for 2024-2025)

- Analysis of radiation effects on microcircuits

- Instrumentation for flow measurement and analysis of cooling system gas mixtures (upgrading):

- Sonar system: flow measurement

- Thermosiphon: real test in April/May

- Microcircuit testing and integration of detection scales

- Integration of a new generation switch (FELIX) in the calorimetric acquisition chain

- Responsible for all pixel and insertable-B layer (IBL) software:

-

CTA

- Development of the CTA cameras event builder

- First light from telescope with CPPM acquisition system

-

KM3NeT

- Infrastructure at La Seyne-sur-Mer and offshore

- Detection lines:

- Qualification of detection lines and ORCA line

- Foot of line (anchor and container)

- Integration of foot of line containers

- Calibration of detection lines and integration on the deployment tool

- Deployment and connection of detection lines in Toulon

- Instrumentation:

- Instrumented line

- Acoustic positioning system

- Anti-fouling system for optical modules

- KM3NeT-France host laboratory

- Interface with Mediterranean Cable Maintenance Agreement: cable maintenance

- Study of the ORCA project for neutrinos oscillations searches

-

Euclid NISP (Near Infrared Spectro-Photometer)

- Detector Responsibilities:

- Ensure the characterization of Euclid flight detectors

- Clean room, cryostats, acquisition bench

- Systems Responsibilities:

- Ensure their integration on the focal plane and their metrology

- Participate in construction and testing (electrical, thermal, vibration)

- Drawing up specifications and test reports

- Manage interfaces

- Support NI-DS product quality assurance

- Integration of simulation production tools

- Simulation tools coordination.

- Detector Responsibilities:

-

imXgam

- PIXSCAN system: spectral tomography

- Data acquisition: reconstruction / data processing (reconstruction code writing)

- Python/C development

- μC programming (arm platform)

- Temporal project: temporal spectrometric imager for the decommissioning of nuclear equipment

- Monte Carlo simulation

- Data acquisition

- PIXSCAN system: spectral tomography

-

LHCb:

- PCIe40 upgrade test and control tools development

-

Madmax/DarkSide

- Development of the calibration system

- Use of AI techniques for event reconstruction

Mechanics

The mechanical department, composed of 16 to 18 people, takes up the challenges launched by our projects. He is involved in the development of complex mechanical assemblies installed in environments as varied as the seabed, particle accelerators, high mountains, space...

We take place from design to dismantling, including manufacturing, installation and maintenance.

Thus, based on the needs of our customers, we design our products using design assistance software (CAD). This definition is validated, if necessary, by finite element calculations.

For the production, we use either subcontracting or in-house manufacturing on our machines (numerical and conventional control). In all cases, the quality of the products is controlled according to defined procedures.

Finally, we have to take place on site to install or maintain our creations in often extreme environments.

Head of the department: Stéphan Beurthey

Membres:

The mechanical department's skills include research and development, design, construction and installation of complex assemblies. The mechanical department has expertise in the following areas:

- static and dynamic structural and thermal calculation using finite elements;

- hydrodynamic calculations ;

- three-dimensional measurement and control ;

- composite and metallic materials ;

- robotics;

- computer-aided design and manufacturing (CAD/CAM);

- project organization and management, quality approach.

The Mechanical Department of the CPPM meets the needs of the laboratory's physics groups regarding studies, mechanical engineering, manufacturing, on-site assembly and maintenance of the work carried out. Some examples of achievements in various environments are presented.

The seabed with MEUST/KM3NeT

We are committed to the development of the KM3NeT underwater telescope, which instruments more than a billion cubic metres of water at a depth of more than 2000 metres. We took charge of the design and installation of the underwater network to connect detectors (lines over 200m high). This infrastructure includes underwater cables to connect the telescope to the coast (40km), connection means (connectors, junction box,...) as well as line feet (interfaces between the network and the detectors). The challenges were enormous because designing a structure that could connect more than 160 lines, reliable over more than 15 years, scalable according to the number of lines installed and maintainable with subsea robots is uncommon even in deep offshore environments. A first part of the network was deployed in 2016 and we are currently working on its extension. We have also defined the procedures for installing and launching the detection lines, always paying close attention to the safety of the crew. Several lines have already been successfully installed.

Particle accelerators with the ATLAS detector

Thanks to the experience acquired by the pixel-based trace detector service with the ATLAS experiment located in the LHC accelerator at CERN, we were in charge of the mechanical coordination of the IBL project (Insertion of a fourth detection layer inside the detector to compensate for its ageing). The installation was successfully completed in 2015. Since then, a more ambitious project, ITK, with five times more pixels than the previous detector, has been launched. Our department plays a major role in the geometric (metrologist, accuracy less than 0.2 mm/m) and thermoelastic (thermal deformations < 1µm/°C) characterization of the detector's carbon structures. Our experience in this type of detector positions us as a key player in the assembly of detection modules. We contribute very actively (through prototypes and tests for example) to the definition of procedures and we are in charge of coordinating the assembly of the detector which should be completed in 2021.

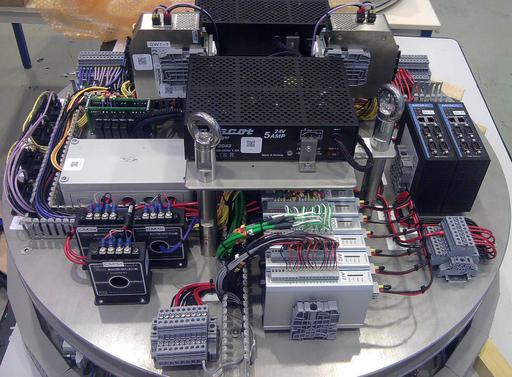

High mountains with LSST

LSST is an 8-metre diameter telescope dedicated to the study of dark energy. Six filters (26 to 44 kg and 80 cm in diameter) are used to select the color of the objects observed. The MPCC is in charge of the system for positioning these filters in front of the telescope camera. Thus, to respect their integrity, the maintenance is carried out by high-precision isostatic mechanisms. Contamination is limited by the appropriate choice of lubricant and surface treatments. The functional safety analysis made it possible to define a control architecture in which a supervisory PLC ensures the consistency of information between sensors and actuators. Since 2015, intense work on the development of a demonstrator on a scale of 1, but also on interfaces with the telescope, has made it possible to validate the design. We are currently in the process of building the final system that will be integrated into the overall filter management system for which the MPCC is responsible for coordinating the construction.

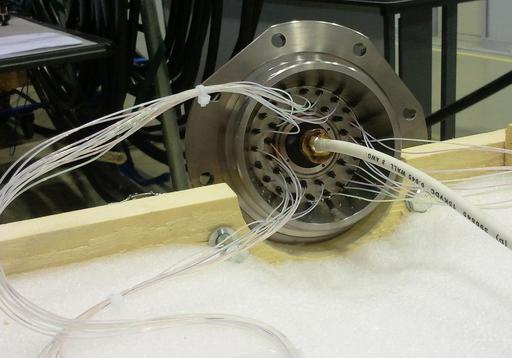

Space with the Euclid mission

Euclid is a space telescope that includes an imager with 16 infrared (IR) detectors. The MPPC is responsible for the qualification of IR detectors and their integration into the focal plane. To do this, we had to build two cryostats. A complex instrumentation has been developed to control the cooling so as not to damage the detectors. Everything is designed to ensure perfect cold alignment and to exclude any thermomechanical stress. The integration of the imager was delicate because the detectors are among the most sensitive elements of the instrument. This assembly, supported by non-contact metrology, required many complex tools. We delivered the imager to CNES at the end of 2018.

_zoom.small.jpg)