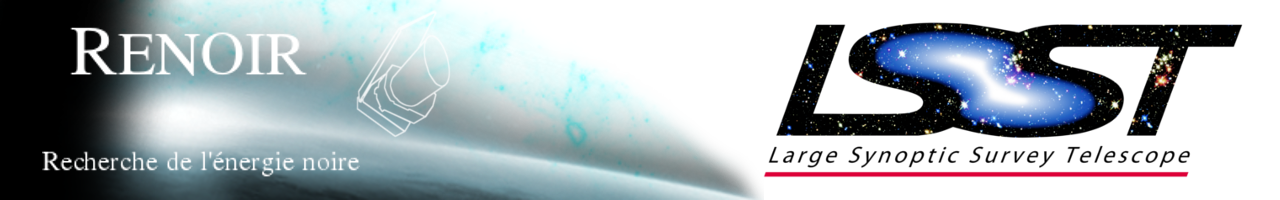

To measure the distance of the galaxies one measures the spectrum of the light that they emit. On LSST, these measurements will be made using six color filters installed on an automated carousel. These six filters are made up of several layers of a dielectric material deposited on a silica substrate. A specific material will be used for each filter.

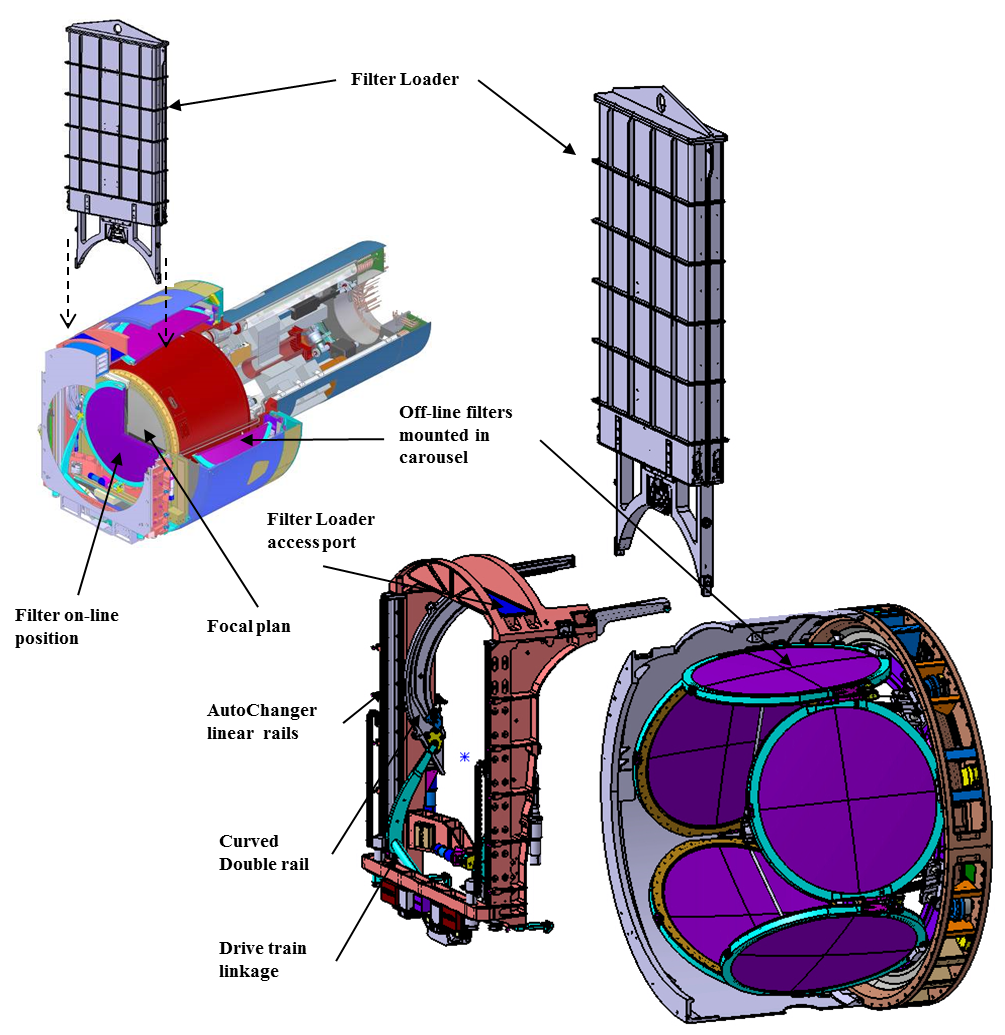

Le système est validé par un banc de test permettant de simuler la configuration réelle de la caméra.The filter exchange system of the camera is composed of three automated systems: a carousel of 5 optical filters, a filter changer (the Auto Changer) which can, at any time, replace one of the 5 Filters in place. The 6th filter can be interchanged in the camera during the day with a filter charger mechanism (the Loader). The system is validated by a test bench to simulate the real configuration of the camera.

Main components of the system Filter exchanger in the LSST Camera

The system is developed by a collaboration of 5 IN2P3 laboratories. Each Laboratory is responsible for the provision of a subsystem. The current development phase is the construction and testing of a prototype at scale 1.

Contribution of the 5 IN2P3 Laboratory

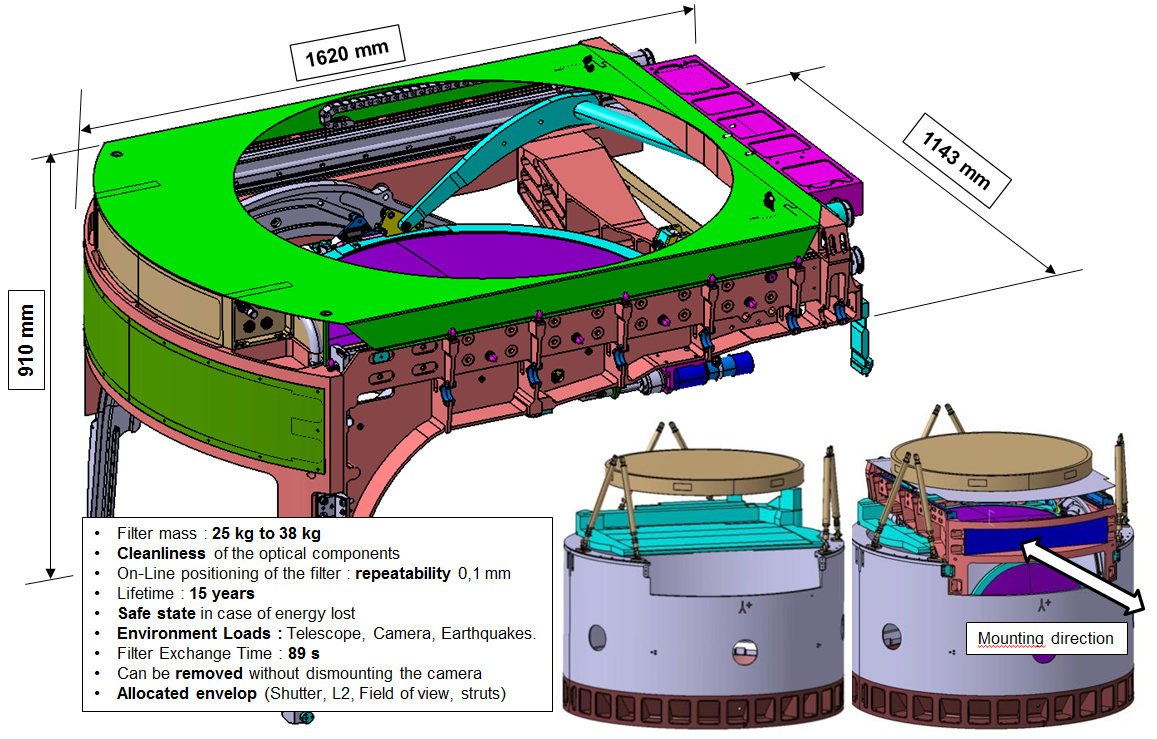

The development of Automatic Changer is ensured at the CPPM by a team of 6 people: Engineers and technicians in mechanics and electronics. The filter changer, which is integrated into the on-board filter change system, must meet the challenges of filter size and fragility, optical cleanliness, position repeatability (<0.1 mm), reduced time For filter change (89 seconds), and a limited volume. The following figure summarizes the main specifications and illustrates the general configuration of the instrument.

Overview of the Auto Changer and its mounting configuration in the camera

The Auto Changer moves the selected filter from its garage position in the carousel to its viewing position in the camera's field of view. The complex filter path is provided by two double groove guide rails in order to control the trajectory and inclination of the filter. The carriages which support the filter are driven by an articulated mechanism fixed on two motorized linear rails. The filter in the position of observation is supported by an isostatic (point-to-plane) clamping system which allows it to be held without stress and with a repeatability better than a tenth of a millimeter.

The automatic changer is supported by an aluminum frame like the structure of the camera to avoid differential dilution in the temperature range -15 ° to 35 ° C.

The control control is provided by a network of motors and sensors driven by a PC 104 via a CANopen bus. The sensors supply independent safety PLCs on the state of the system, the controllers control the power supply to the actuators in order to avoid bad maneuvers such as collisions or the fall of the filter.

The qualifier for the Automatic Changer will be validated in 2017 by tests on a 1-scale demonstrator built in 2016. The final Automatic Changer will be integrated on the camera in the USA (SLAC) in 2018.

Demonstrator at scale 1 of the Auto Changer built in 2016

By Pierre Karst